Customer Success

Results That Build Reliability

Sterling

Silver Jewelry

Pure Authentic Silver

Authentic Gemstone

Jewelry

925 Silver Shine works in a unique way through which, we ensure that our Manufacturing Process becomes symmetrical and accepted by everyone. Now we are going to show you how we make it possible, creating the Best 925 Sterling Silver Jewelry for you.

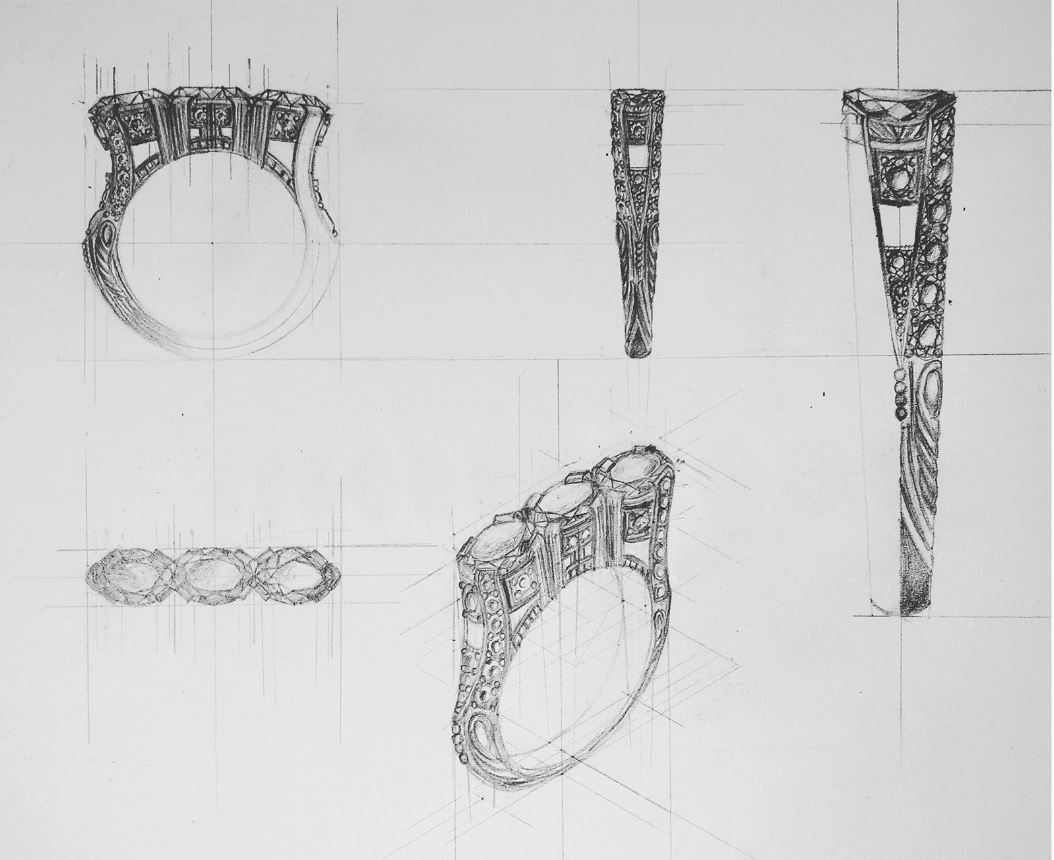

This is the first step for crafting a Beautiful Jewelry. In this process, our Designers design the overall structure of the Jewelry. Threw that outline we can imagine the actual shape and Structure of the Jewelry. We use different styles of Designs that make our Rings, Necklaces, Earrings, Bangles, and Bracelets a unique Identity. We also ensure that what type of Gemstone will be appropriate for the jewelry in this same process. Here we accept any designs from our customers and we work on those designs as well.

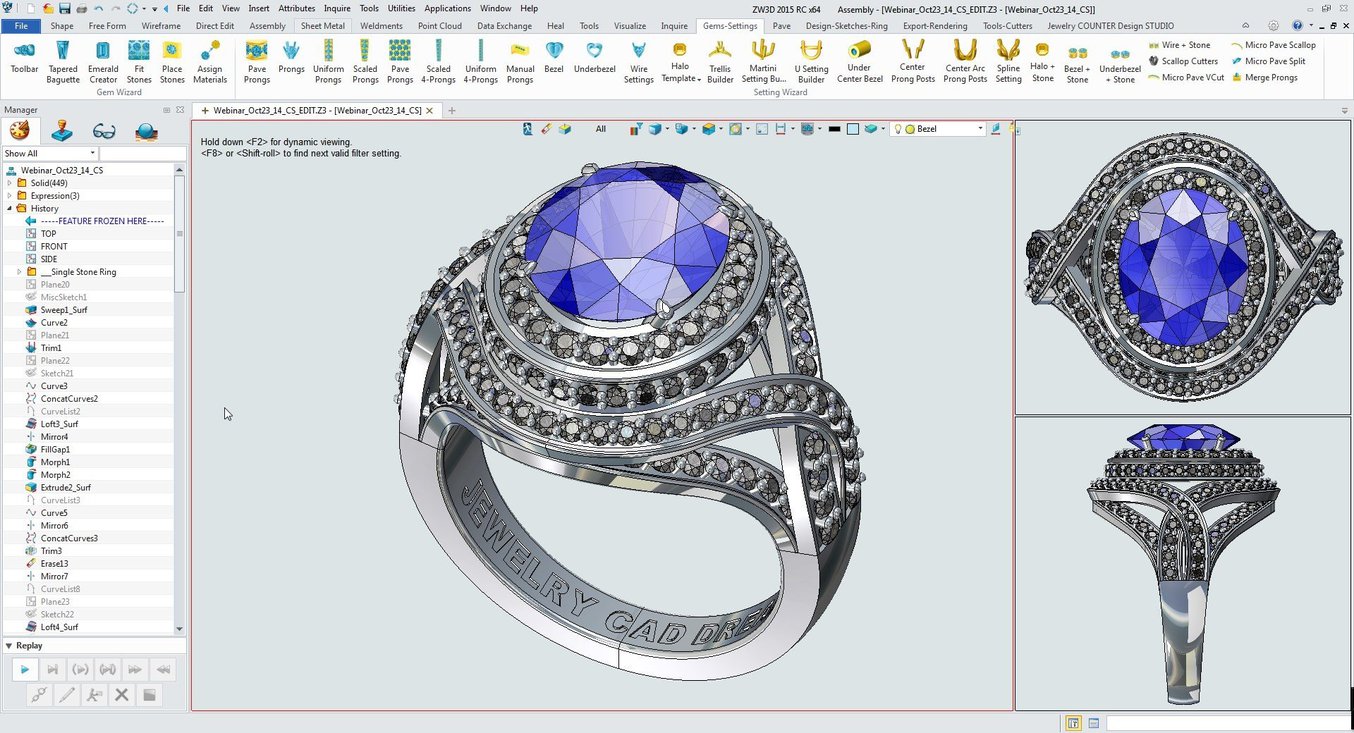

This is the second step of Crafting a Jewelry. In this process, we use CAD( Computer Aided Designing) software which helps us to outline the overall structure of the jewelry. This is a 3D software which allows us to measure the dimensions and Quality of the Jewelry. After that, we use CAM( Computer Aided Manufacturing) software which allows us to automate the whole process of Machinery.

This is the third process in which we Communicate with the Customer and work on the.

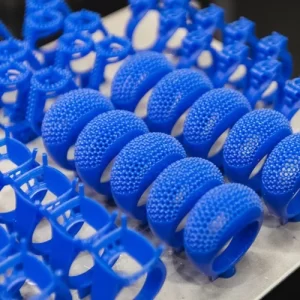

In this process, we make a Model of the jewelry with 3D printing, Clay, or wax to get the proper idea of the Finalize product. This helps us to see how the product will look when it is completely crafted.

In this step, we create a Rubber mold of the Jewelry which helps us in the production process of the Jewelry. This process allows us to create the exact replica of the Jewelry that we finalize and it allows us to get more accessibility in crafting Jewelry.

In this step, we create a wax casting structure. We use rubber molds to create a wax replica of the Jewelry and attach that wax Jewelry to a stem at a 45-degree angle which gives a tree effect. This wax tree is the essence of Casting the Sterling Silver Jewelry.

This is the next step in Jewelry making, through which we melt different metals like Gold, Silver, Copper, and Platinum as per the requirement of the jewelry. Then we prepare a casting stand in which we place our Wax tree and we drip the melted metal in that wax mold, which takes the shape of a wax tree but now it is in the metal of our choice. When the metal is cooled down we can see the finalized Jewelry pieces.

In this process, we separate every piece of product from the tree, grind the Jewelry in different shapes, and remove any excess metal or impurities from the jewelry. Our polishers use a motorized Grinding machine to polish Each piece of Jewelry.

In this step, our talented craftsman gives a hand touch to each single piece of jewelry. They remove any excess metal or particles of wax mold from the jewelry by their hands using filing. After this, we combine 2 pieces of the same jewelry with soldering or laser technique.

Next, we polish the jewelry which increases the value of the product. Majorly we use three types of polishing techniques: tumbling, pre-polishing, and ultra-cleaning. We do polishing before because after the gemstone is set in the jewelry complete polish of the product is not possible.

Gemstone assorting is a crucial process in this crafting process, through which we choose authentic and genuine gemstones for the Jewelry.

Then we finalize the gemstone by checking its cuts, quality, and overall structure. Then we set particular gemstones carefully in the jewelry. This flawless process helps us to craft the perfect and beautiful Jewelry for you.

This is the final polishing process in which we polish the Jewelry with Gemstones intact through soft buff, solid buff, and hair buff. This process gives a shiny tint to the jewelry and removes any unwanted material from the Jewelry.

This is the final process in the whole Jewelry making. In this stage, we cover the entire jewelry with Rhodium which helps give the whole jewelry a protective shield against Scratches and tarnishes.

It is applied to yellow gold to give it an appealing look and Design. It is applied to white gold to increase its whiteness because natural white gold is not very white.

Please note we Order Customized Jewelry last week and, have received the shipment This Monday, and we have checked all production. 1st of All, we would like to thank you for this amazing job, we are very very happy with our jewelry! This is our 1st collection of jewelry, and we are very grateful with the work you have done for us Thank you so much. “Sharing My New Designs soon.”

Lightweight, unique design love the little Studs..also, love how unique the earrings are, and not the typical Necklace that come with a Handcrafted Natural Gemstones.

22 Years Works with 925 Silver Shine, The workmanship is exquisite and designs are unique. Extremely happy with every purchase I have made so far