Welcome to the fascinating world of jewelry manufacturing at 925 Silver Shine, where exquisite craftsmanship and timeless beauty come together. As experts in the art of jewelry production, we take immense pride in our meticulous attention to detail and commitment to delivering high-quality pieces that captivate hearts.

With our state-of-the-art facilities and a team of skilled artisans, we ensure that each piece of jewelry is crafted with precision and care. Our manufacturing process involves multiple intricate stages, from design conceptualization to the final polishing, with every step tailored to create stunning masterpieces.

At 925 Silver Shine, we go beyond just making jewelry; we strive to create cherished memories. Our wide range of elegant designs incorporates traditional and contemporary elements, catering to every style and occasion. Whether you’re looking for a classic engagement ring, a statement necklace, or delicate sterling silver hoop earrings, we have a piece that perfectly complements your taste.

Experience the artistry and passion that go into every piece of jewelry at 925 Silver Shine. From concept to creation, we guarantee timeless beauty that lasts a lifetime. Step into our world and indulge in the beauty that jewelry can bring.

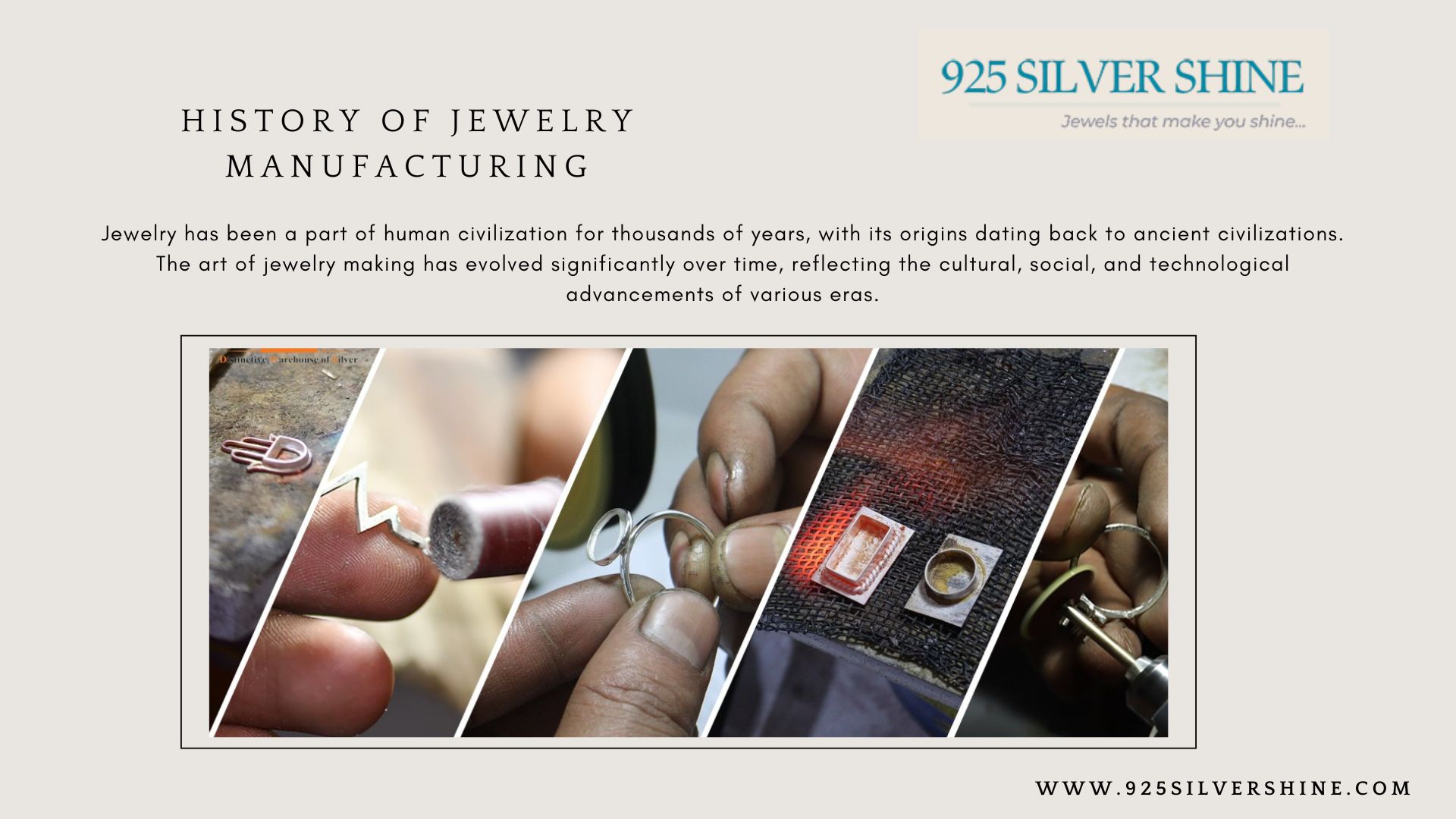

History of Jewelry Manufacturing

Jewelry has been a part of human civilization for thousands of years, with its origins dating back to ancient civilizations. The art of jewelry making has evolved significantly over time, reflecting the cultural, social, and technological advancements of various eras.

In the early days, jewelry was often crafted from natural materials such as shells, bones, and stones, which were readily available. As civilizations progressed, the use of precious metals like gold and silver became more prevalent, allowing for the creation of more intricate and sophisticated designs. The ancient Egyptians, Greeks, and Romans were known for their exceptional jewelry-making skills, incorporating complex techniques like granulation, filigree, and enameling into their creations.

During the Middle Ages, the art of jewelry making flourished in Europe, with the emergence of guilds and workshops dedicated to the craft. Artisans honed their skills, passing down techniques from generation to generation. The Renaissance period saw a resurgence of interest in jewelry, with the incorporation of gemstones and the development of new styles that reflected the opulence and grandeur of the era.

The Industrial Revolution of the 19th century revolutionized the jewelry industry, introducing mass-production methods and making jewelry more accessible to the general public. The 20th century witnessed a diverse range of jewelry styles, from the elegant Art Nouveau and Art Deco movements to the bold and innovative designs of contemporary jewelry makers. Today, the jewelry manufacturing company continues to evolve, embracing new technologies, materials, and design concepts to create timeless pieces that captivate and inspire.

Materials Used in Jewelry Manufacturing

The world of jewelry manufacturing is a vast and diverse one, with a wide range of materials used to create the exquisite pieces we cherish. At the heart of this industry lies the pursuit of crafting the finest and most durable jewelry, and the choice of materials plays a crucial role in achieving this goal.

One of the most prominent materials used in jewelry manufacturing is precious metals, such as gold, silver, and platinum. These metals possess unique properties that make them ideal for jewelry-making, including their malleability, durability, and resistance to corrosion. Gold, in particular, has long been revered for its timeless beauty and symbolic significance, making it a popular choice for engagement rings, wedding bands, and other fine jewelry.

In addition to precious metals, semi-precious stones and gemstones have also become an integral part of the jewelry industry. From sparkling diamonds and radiant rubies to mesmerizing emeralds and captivating sapphires, these natural wonders add depth, color, and brilliance to jewelry designs. The careful selection and precise cutting of these gemstones require exceptional skill and expertise, ensuring that each piece is a true work of art.

Beyond the traditional precious metals and gemstones, modern jewelry manufacturing has also embraced the use of innovative materials, such as titanium, tungsten, and ceramic. These materials offer unique properties, such as hypoallergenic qualities, scratch resistance, and a contemporary aesthetic, appealing to a diverse range of consumers. The incorporation of these materials has expanded the creative possibilities for jewelry designers, allowing them to push the boundaries of traditional jewelry-making.

The choice of materials in jewelry manufacturing is not only about aesthetics but also about ensuring the durability and longevity of the pieces. Careful consideration is given to the properties of each material, their compatibility with other components, and their ability to withstand the rigors of everyday wear. This commitment to quality and craftsmanship is what sets the jewelry industry apart, ensuring that the pieces created will be cherished for generations to come.

Jewelry Manufacturing Techniques

The art of jewelry manufacturing is a captivating blend of traditional techniques and modern innovations, each step meticulously executed to bring forth the most exquisite creations. At the heart of this process lies a deep understanding of the materials, tools, and methods that have been honed over centuries, creating a symphony of skill and artistry.

One of the foundational techniques in jewelry manufacturing is casting, a process that involves pouring molten metal into a mold to create the desired shape. This method allows for the production of intricate and complex designs, from delicate filigree to bold statement pieces. The lost-wax casting technique, in particular, has been a staple in the industry, enabling the realization of even the most intricate visions.

Another essential technique is fabrication, which involves the shaping, joining, and manipulating of metal components to create the final jewelry piece. This can include techniques such as soldering, hammering, and wire-wrapping, each requiring a high level of precision and craftsmanship. Skilled artisans meticulously work with these techniques, transforming raw materials into captivating masterpieces.

Fabrication and Metalwork: Crafting the Foundation of Fine Jewelry

The art of stone setting is another crucial aspect of jewelry manufacturing, where gemstones are carefully selected and secured into the metal setting. From the classic prong setting to the intricate pavé and channel settings, each technique enhances the beauty and brilliance of the gemstones, creating a harmonious union of form and function.

In recent years, the jewelry industry has also embraced the use of advanced technologies, such as computer-aided design (CAD) and 3D printing, to streamline the manufacturing process and explore new design possibilities. These innovations have allowed for the creation of more complex and customized pieces, catering to the ever-evolving preferences of modern consumers.

Regardless of the techniques employed, the true essence of jewelry manufacturing lies in the dedication and artistry of the skilled craftsmen who pour their hearts into every piece they create. From the initial conceptualization to the final polishing, each step is executed with meticulous attention to detail, ensuring that the resulting jewelry not only captivates the eye but also speaks to the soul.

Trends in Jewelry Manufacturing

The jewelry industry is a dynamic and ever-evolving landscape, constantly adapting to the changing preferences and demands of consumers. As trends come and go, jewelry manufacturers must stay attuned to the pulse of the market, embracing new materials, designs, and production techniques to remain relevant and captivate their audience.

One of the prominent trends in the jewelry manufacturing industry is the increased focus on personalization and customization. Consumers today seek unique and personalized pieces that reflect their individual style and preferences. Jewelry manufacturers have responded to this demand by offering a wide range of customization options, from engraving and monogramming to the ability to mix and match different components to create a one-of-a-kind piece.

Sustainability has also emerged as a significant trend in the jewelry industry, with consumers becoming more conscious of the environmental and ethical impact of their purchases. Jewelry manufacturers have embraced this shift, exploring the use of recycled and ethically sourced materials, as well as implementing eco-friendly production processes. The rise of lab-grown diamonds, for instance, has provided a sustainable alternative to mined diamonds, catering to the growing demand for more ethically conscious jewelry.

Embracing Technology: Innovation in Design and Manufacturing Techniques

Another notable trend in jewelry manufacturing is the incorporation of technology and innovation. The use of computer-aided design (CAD) software, 3D printing, and advanced manufacturing techniques has revolutionized the industry, allowing for the creation of intricate and highly precise designs. These technological advancements have not only streamlined the production process but also opened up new avenues for creative expression, enabling jewelry designers to push the boundaries of traditional jewelry-making.

The influence of global trends and cultural diversity has also shaped the jewelry manufacturing landscape. Designers and manufacturers are drawing inspiration from various cultural traditions and incorporating elements of different artistic styles into their creations. This cross-pollination of ideas has resulted in a rich tapestry of jewelry designs that cater to the diverse preferences of a global audience.

As the jewelry industry continues to evolve, manufacturers must remain attuned to the changing tides of consumer preferences and industry dynamics. By embracing innovation, sustainability, and a deep understanding of their target market, jewelry manufacturers can create timeless pieces that captivate and inspire, ensuring their enduring relevance in the ever-shifting world of jewelry.

Quality Control in Jewelry Manufacturing

At the heart of the jewelry manufacturing industry lies a steadfast commitment to quality, ensuring that every piece that leaves the workshop or factory is a testament to the artistry and craftsmanship of the makers. This unwavering dedication to quality control is what sets the industry apart, guaranteeing that the jewelry adorning the necks, wrists, and fingers of consumers is not only visually stunning but also durable and long-lasting.

The quality control process in jewelry manufacturing begins with the careful selection and sourcing of raw materials. From precious metals to gemstones, each component is meticulously inspected to ensure it meets the highest standards of quality and purity. This attention to detail continues throughout the manufacturing process, with each step subjected to rigorous quality checks to identify and address any potential issues before the final product is assembled.

One of the critical aspects of quality control in jewelry manufacturing is the adherence to industry standards and regulations. Jewelry manufacturers must comply with a range of certifications and hallmarks that attest to the quality and authenticity of their products. For instance, the 925 stamp on silver jewelry indicates that the piece contains at least 92.5% pure silver, while the Karat (K) system ensures the purity of gold jewelry. These hallmarks not only provide consumers with a guarantee of quality but also help to maintain the integrity of the industry as a whole.

Craftsmanship and Precision: The Hallmarks of Quality Control in Jewelry Manufacturing

In addition to material quality, jewelry manufacturers also place a strong emphasis on the precision and craftsmanship of their products. Each piece is meticulously inspected at various stages of the manufacturing process, from the initial design and casting to the final polishing and assembly. This attention to detail ensures that the finished product meets the highest standards of fit, finish, and overall aesthetic appeal.

The role of quality control extends beyond the manufacturing process and into the post-production phase as well. Jewelry manufacturers often provide comprehensive warranties and aftercare services to their customers, ensuring that any issues or concerns are promptly addressed. This commitment to customer satisfaction further reinforces the brand’s reputation for quality and reliability, fostering a lasting relationship with consumers.

By upholding the highest standards of quality control, jewelry manufacturers not only create exceptional products but also cultivate a sense of trust and loyalty among their customers. This unwavering dedication to excellence is what sets the jewelry industry apart, ensuring that each piece that adorns its wearer is a testament to the timeless beauty and unparalleled craftsmanship that defines the world of jewelry.

The Role of Technology in Jewelry Manufacturing

The jewelry manufacturing industry has undergone a significant transformation in recent years, driven by the rapid advancements in technology. From the design phase to the production process and beyond, technology has become an integral part of the jewelry-making landscape, revolutionizing the way artisans and manufacturers approach their craft.

One of the most significant technological developments in the jewelry industry is the widespread adoption of computer-aided design (CAD) software. This powerful tool has enabled jewelry designers to explore and create intricate, three-dimensional designs with unprecedented precision and efficiency. By utilizing CAD, designers can experiment with different shapes, textures, and gemstone placements, allowing them to bring their visions to life with remarkable accuracy before even touching a physical material.

The role of technology in jewelry manufacturing extends beyond the design and prototyping stages. Modern jewelry workshops and factories have embraced the use of computer-controlled machinery and automation to streamline the production process. From laser cutting and engraving to precision stone setting and polishing, these technological advancements have not only increased efficiency but also enhanced the overall quality and consistency of the final products.

3D Printing: Revolutionizing Prototyping and Production in Jewelry

Alongside CAD, the integration of 3D printing technology has further transformed the jewelry manufacturing process. This innovative technique allows for the creation of highly detailed, customized prototypes and even the direct production of final jewelry pieces. The ability to 3D print wax or resin models, which can then be cast in precious metals, has revolutionized the industry, empowering designers to bring their most complex and unique ideas to reality.

Furthermore, the integration of digital tools and software has revolutionized the way jewelry manufacturers manage their operations. From inventory tracking and order management to customer relationship management and e-commerce platforms, technology has enabled jewelry businesses to optimize their workflows, improve communication, and better serve their clientele. This digital transformation has also paved the way for enhanced data analysis, allowing manufacturers to make more informed decisions and stay ahead of industry trends.

As the jewelry industry continues to evolve, the role of technology will only become more crucial. Emerging technologies, such as augmented reality and virtual try-on applications, are already transforming the way consumers engage with and purchase jewelry. By embracing these innovations, jewelry manufacturers can enhance the customer experience, foster deeper connections, and maintain their competitive edge in an increasingly digital landscape.

The integration of technology in jewelry manufacturing has undoubtedly been a game-changer, empowering designers, artisans, and manufacturers to push the boundaries of creativity and efficiency. As the industry continues to evolve, the strategic adoption of technological advancements will be essential for jewelry brands to remain at the forefront of innovation and captivate the hearts and minds of their discerning clientele.

Sustainability in Jewelry Manufacturing

In an era of heightened environmental consciousness, the jewelry industry has been compelled to re-evaluate its practices and embrace a more sustainable approach to manufacturing. As consumers become increasingly mindful of the impact their purchases have on the planet, jewelry brands and manufacturers have responded by implementing innovative solutions that prioritize sustainability and ethical sourcing.

One of the key areas of focus in sustainable jewelry manufacturing is the use of ethically sourced materials. This encompasses the responsible procurement of precious metals, such as gold and silver, as well as the ethical mining and procurement of gemstones. Many jewelry brands have partnered with organizations that certify the origin and production methods of these materials, ensuring that they are extracted and processed in a manner that minimizes environmental and social harm.

In addition to ethical sourcing, jewelry manufacturers have also explored the use of recycled and reclaimed materials. By repurposing existing gold, silver, and other metals, these companies are able to reduce the demand for new resource extraction, thereby lowering their carbon footprint and contributing to a more circular economy. This commitment to recycling not only benefits the environment but also allows for the creation of unique and one-of-a-kind jewelry pieces that resonate with the growing eco-conscious consumer base.

Recycled Materials: Reducing Environmental Impact Through Repurposing

The adoption of sustainable manufacturing techniques has also been a crucial aspect of the jewelry industry’s shift towards environmental responsibility. From the use of energy-efficient equipment and renewable energy sources to the implementation of waste management and water conservation practices, jewelry manufacturers are actively working to minimize their environmental impact throughout the production process. These efforts not only reduce the carbon footprint of the industry but also inspire other sectors to follow suit in the pursuit of a more sustainable future.

Beyond the manufacturing process, jewelry brands are also exploring innovative ways to promote sustainability in their product offerings and business operations. This includes the introduction of lab-grown diamonds and other man-made gemstones, which offer a more environmentally friendly alternative to mined stones. Additionally, some jewelry companies have implemented take-back programs, allowing customers to responsibly dispose of their old or unwanted jewelry, which can then be repurposed or recycled.

The shift towards sustainability in the jewelry industry is not just a passing trend but a fundamental transformation that is reshaping the way the sector operates. By embracing eco-friendly practices, ethical sourcing, and innovative solutions, jewelry manufacturers are not only meeting the evolving demands of their customers but also contributing to the larger global movement towards a more sustainable future. As the industry continues to evolve, the commitment to sustainability will remain a driving force, ensuring that the beauty and allure of jewelry is matched by its environmental and social responsibility.

Famous Jewelry Manufacturers

The jewelry manufacturing industry is home to a rich tapestry of renowned brands and artisans, each with their own unique stories, design aesthetics, and legacies. These famous jewelry manufacturers have not only captivated the hearts and minds of consumers but have also significantly influenced the trajectory of the industry as a whole.

One of the most iconic and prestigious names in the jewelry world is Cartier, a French luxury brand that has been synonymous with exquisite craftsmanship and timeless elegance since its inception in 1847. Cartier’s reputation for creating masterpieces, from the iconic Love bracelet to the captivating Panthère collection, has cemented its status as a true leader in the industry. The brand’s unwavering commitment to quality, innovation, and storytelling has earned it a loyal following among the world’s most discerning clientele.

Cartier: A Legacy of Timeless Elegance

Another renowned jewelry manufacturer is Tiffany & Co., the American luxury brand that has captivated the world with its distinctive blue boxes and signature designs. Tiffany’s legacy dates back to 1837, and the company has since become synonymous with timeless elegance, exceptional craftsmanship, and a commitment to social responsibility. From the iconic Tiffany Setting engagement ring to the elegant Tiffany T collection, the brand’s creations have become cherished symbols of love, success, and personal style.

The Swiss watchmaking and jewelry powerhouse, Rolex, is also widely recognized for its exceptional craftsmanship and innovative designs. While primarily known for its prestigious watches, Rolex has also made a significant mark in the jewelry industry, creating exquisite pieces that seamlessly blend technical precision with refined aesthetics. The brand’s commitment to quality, durability, and precision has earned it a reputation as a true icon in the world of luxury accessories.

0 Replies to “Unveiling the Intricate World of Jewelry Manufacturing at 925 Silver Shine”